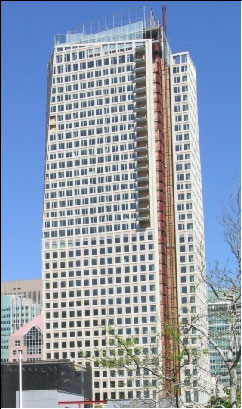

Millennium Tower ( 301 Mission St. ), San Francisco, CA

60-Story, poured-in-place concrete …The fourth tallest building in San Francisco, and California’s tallest reinforced concrete structure.

Owner: Millenium Partners

General Contractor: Webcor Builders

Reinforcing Steel Sub-Contractor: RPS Regional Steel

Structural Engineer: DeSimone Consulting Engineers

Architect: Handel Architects

BauGrid Manufacturer and Supplier: Delta Building Systems

|

|

|

|

|

|

Pacific Beacon, San Diego, CA

18-Story, poured-in-place concrete

Owner: U.S. Navy / Clark Pinnacle

General Contractor: Clark Construction

Reinforcing Steel Sub-Contractor: RCI

Structural Engineer: Flores Lund Consultants

Architect: Torti Gallas and Partners

BauGrid Manufacturer and Supplier: Delta Building Systems

|

|

Hard Rock Hotel, San Diego, CA

12-story Mixed Use, poured-in-place concrete

Owner: Hard Rock Hotel

General Contractor: Turner Construction

Reinforcing Steel Sub-Contractor: RCI

Structural Engineer: KPFF

Architects: Carrier Johnson

BauGrid Manufacturer and Supplier: Delta Building Systems

|

|

|

|

|

|

|

Grand Del Mar, Del Mar, CA

3-Story, 5-Star Resort – Poured-in-place concrete

Owner: Manchester Grand Resorts

General Contractor: Turner Construction

Reinforcing Steel Sub-Contractor: Fontana Steel

Structural Engineer: KPFF

Architects: Altevers Associates

BauGrid Manufacturer and Supplier: Delta Building Systems

|

|

St. Regis Museum Tower, San Francisco, CA

42-Story Poured-in-Place Mixed Use Building

Developer: Starwood Hotels and Carpenter & Company

Lead Design Architect: Skidmore, Owings & Merrill

General Contractor: Webcor Builders

Concrete Contractor: Webcor Concrete

Reinforcing Steel Sub-Contractor: RPS Regional Steel

|

|

|

|

|

|

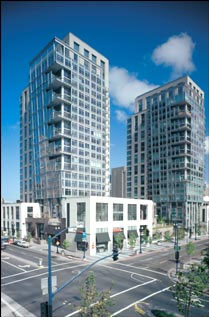

Paramount Building, San Francisco, CA

39-Story Pre-cast Concrete Structure

The World's Tallest Precast Concrete building in a region of highest seismicity.

Co-winner of Pre-cast / Pre-stressed Concrete Institute (PCI) 2002 Harry H. Edwards Industry Advancement Award.

Owner: The Related Companies

General Contractor: Charles Pankow Builders

Precast Conc. Sub-Contractor: Mid-state Pre-cast

Structural Engineer: Robert Englekirk Consulting Structural Engineers, Inc.

Architects: Kwan Henmi, Architecture and Planning and Elkus/Manfredi Architects, Ltd. |

|

Ocean Villas Towers, Long Beach, CA

Two 22-story Tunnel-formed Poured in Place Towers

World’s Tallest Tunnel Formed Structures in Region of Highest Seismicity

Owner: Genesis Real Estate Group, Inc., Dallas, TX

Architect: EDI Architecture, Inc., Houston, TX

Structural Engineer: Englekirk Partners Consulting Structural Engineers, Inc., Orange County, CA

General Contractor: Summit Builders Construction Co., Irvine, CA

Concrete Sub-Contractor: Highrise Concrete Systems, Inc., Irving, TX |

|

|

|

|

|

Renaissance Plaza, San Diego, CA

Two 23-story Poured in Place Towers

Winner: Structural Engineers Association of California (SEAOC) 2003 Structural Engineering Excellence Award – Best Use of Conventional Techniques in New Building Construction

Developer: Lambert Development LLC

Contractor: Roel Construction, San Diego

Engineer: KPFF, San Diego

Architect: Carrier Johnson

Reinforcing Steel Sub-Contractor: J. L. Davidson, Santee, CA

|

|

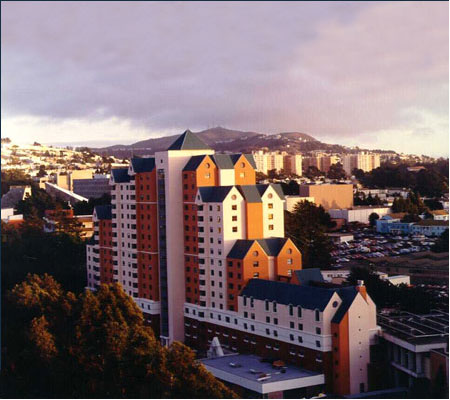

SF State Dormitory, San Francisco, CA

17- Story student dormitory on campus at SFSU was built in 1989. Baumann Engineering was brought into the project in 1987. At that time, Baumann Engineering proposed the use of a product called (at that time) MedoMesh, which was a product he had invented and was working to develop with a company called Meadow Steel.

Agreement was reached to perform tests at the University of California , Irvine, which showed that using the new reinforcement product, the ductility of the building was increased, and so the earthquake forces the building must be designed to withstand could be calculated at a lower level. This allowed a redesign of the building which reduced 10" thick shearwalls to 7" thick shearwalls, dramatically reducing the client's costs of materials (concrete, rebar, lap steel), equipment (crane time was reduced) and labor (manual assembly drastically reduced labor.

The UC Board of Regents at the time included several engineers, and it was agreed that the Board would review the proposed design, which it did, and then approved it. When the building was about 90% complete (at about the 14th story, however most of the square footage is below the 14th floor) the Loma Prieta earthquake struck. Despite its proximity to the San Andreas Fault (approx. 1.5 miles), upon inspection Baumann Engineering found no evidence of earthquake damage, not even hairline cracks often associated with new concrete. |

|

|

|

|